ORE SORTING EQUIPMENT

This machinery is used to separate valuable minerals from waste material in mining operations. This equipment utilises various technologies such as optical sensors and X-ray.

This advanced technology is expertly designed for fine ore across a range of sizes, specifically from 16 to 120 mesh. Its innovative double-layer re-sorting system guarantees a low take-out ratio and exceptional sorting precision. Constructed from high-density alloy materials, the chutes are built to endure wear and scratching effortlessly. With low energy consumption, the system features an ultra-high-frequency solenoid valve that drastically reduces losses while providing robust anti-dust and fog protection for environmental sustainability. Furthermore, the suspended cleaning equipment ensures unparalleled accuracy in dusty environments. This solution is the pinnacle of industry standards, showcasing a four-lens single chute design equipped with 128 ejector valves per chute.

This technology is designed for fine ore of various sizes, specifically from 16 to 120 mesh. It incorporates a double-layer system for re-sorting, which achieves a low take-out ratio and high sorting accuracy. Constructed from high-density alloyed materials, the chutes are engineered to withstand wear and scratching. The system operates with low consumption and utilizes an ultra-high-frequency solenoid valve, significantly minimizing loss while offering anti-dust and fog protection for environmental considerations. Furthermore, the suspended cleaning equipment ensures high accuracy in dusty environments. This solution represents the highest configuration in the industry, featuring a four-lens single chute design with 128 ejector valves per chute.

Designed for medium and small mineral particles between 16mm and 40mm in size, this system features an invisible multi-path light back-off mechanism that significantly enhances detection accuracy and system stability. The new discharge system incorporates high-frequency ejector valves, ensuring precise removal and minimal loss. Additionally, the ore-specific AI algorithm, in conjunction with AAP, facilitates intelligent detection and streamlined control.

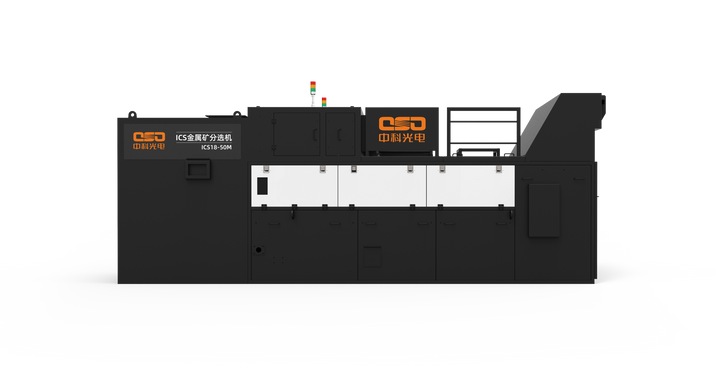

This machine's technical application is highly versatile, suitable for sorting both non-metallic and metallic ores. It can efficiently sort ore in both wet and dry conditions, with sizes ranging from 1 to 5 cm. The innovative design addresses the issue of ore adhesion to the belt during wet processing. With an advanced optical path and a waterproof structure, it significantly enhances the sorting efficiency of waterlogged materials. The optional integration of deep learning technology has improved the detection rate for complex materials while effectively reducing carry-over rates. Additionally, a new generation of hardware and electrical architecture ensures stable and efficient operation.

This machine is highly adaptable, designed for sorting both non-metallic and metallic ores. It effectively sorts ore in both wet and dry environments, accommodating sizes from 1 to 5 cm. Featuring a double belt and a multi-optical path compensation system, it provides finer detection and enhanced stability. Additionally, its new structure includes a high-speed spare valve for accurate rejection and reduced loss. The far-focused open design, along with an innovative dust cleaning and removal system, ensures more stable operation. An ore-specific AI algorithm, paired with a remote app, enhances detection intelligence and operational convenience. The entire machine utilizes a new ore-specific system with an optional deep learning module, broadening the sorting range and improving efficiency.

This Ore Sorter is designed for sorting raw ore particles ranging from 30-100mm. It is effective for wet ore dressing and can separate ores with varying water content. Ideal for the pre-concentration and rough separation of both metal and non-metal ores based on color differences, it utilizes energy-gathering gas cannon ejectors for efficient large particle sorting. The ultra-wide belt feeding system ensures high capacity and stable removal, while the innovative shadowless light technology addresses shadow issues associated with large ore particles, significantly enhancing recognition rates. An advanced AI algorithm enables intelligent sorting of complex materials.

The multi-functional salt sorting machines are engineered for processing highly corrosive materials, including salt and sweeteners, within a mesh range of 8 to 120. Equipped with a fifth-generation FPGA chip, these machines deliver improved operational efficiency. The innovative dissipative optical path design incorporates an AI algorithm specifically for salt detection, enabling enhanced precision. Furthermore, the incorporation of a high-frequency solenoid valve facilitates precise cleaning, while the food-grade 316 L stainless steel body ensures stable and reliable operation. Internet and mobile app connectivity provides convenient control options.

Industry first to use fluorescence to sort 2mm-30mm tungsten-bearing minerals. Intel's fifth generation FPGA chips make computing more efficient. The dissipative fluorescent light path design is equipped with a special AI algorithm for tungsten ore to make detection more subtle. The new high-frequency ejector valves with air suspension makes rejection more accurate. Internet and APP makes control more convenient.

This series features a comprehensive angle scattering self-correction detection system that ensures precise imaging of materials enhances detection sensitivity. It includes dependable, specialized equipment for ore sorting, tailored for varying gas volumes and frequencies, while also being cost-effective and easy to maintain. The independent conveying structure allows for simple disassembly, with actively stabilized materials that reduce acceleration distance, resulting in a compact model with high capacity. Additionally, the dual X-ray detection module offers improved atomic resolution and sorting accuracy, effectively identifying materials with lower ray energy. The leading anti-blocking structure includes a high-frequency electromagnetic ejectors, providing flexible configuration options for high-frequency specifications and air volumes, all while maintaining low consumption, high efficiency, and safety.